Service Details

Powder Coating Services - Durable Finishing with 7 Tank Pre-Treatment Process

At Anand Engineering Works, we provide high-quality powder coating services with a complete 7-tank pre-treatment process that ensures superior surface preparation, corrosion resistance, and long-lasting finish.

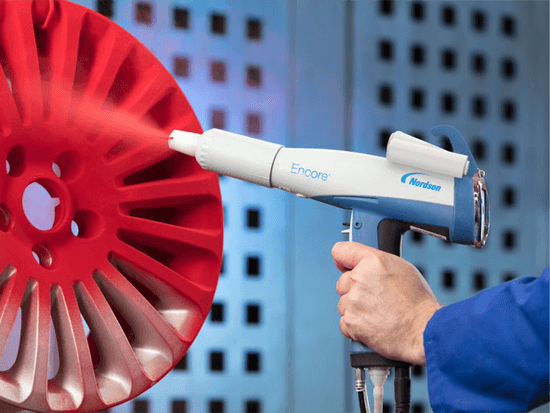

Our powder coating division is equipped with advanced cleaning, drying, and coating systems - delivering smooth, durable, and aesthetically perfect finishes for all types of metal components.

We specialize in coating Mild Steel (MS), Aluminum, and other metal substrates with precision-engineered pre-treatment and powder application systems that meet industrial performance and appearance standards.

Comprehensive 7 Tank Pre-Treatment Process

Our 7-tank process ensures optimal adhesion and surface durability before coating.

The system includes both Dip (Immersion) and Spray (Tunnel Type) cleaning and chemical pre-treatment lines, allowing flexibility for different component types and sizes.

Our pre-treatment line includes:

- Degreasing and Cleaning: Removes oil, dust, and contaminants for a clean base.

- Water Rinse (1 & 2): Ensures complete removal of residual cleaning agents.

- Derusting/Deoxidizing: Treats metal surface for uniformity and corrosion protection.

- Phosphating: Creates a microcrystalline layer to enhance paint adhesion.

- Water Rinse (Final): Ensures a clean, neutral surface before coating.

- Passivation: Provides an anti-rust protective layer before drying.

- Drying: Prepares components for powder coating.

The entire process is supported by Hot Water Generators for temperature-controlled cleaning and Hot Air Drying Ovens for perfect surface preparation prior to coating.

Infrastructure and Equipment

- Pre-Treatment Tanks: Custom-sized tanks to handle components of varied shapes and dimensions.

- Material Handling Systems: Hoists, cranes, and baskets for safe component transfer.

- Hot Water & Air Systems: Efficient temperature control for consistent coating quality.

- Powder Application Booths: For uniform electrostatic powder application.

- Curing Ovens: Controlled temperature systems for proper bonding and finish strength.

We are partnered with leading chemical suppliers, offering a wide range of cleaners, phosphating agents, and pre-treatment chemicals for different metals - ensuring the most suitable process for each customer’s requirement.

Why Choose Anand Engineering Works for Powder Coating

- Complete 7 Tank Pre-Treatment Line: Superior adhesion and corrosion resistance

- Durable Finish: Smooth, even coating that resists impact, UV, and wear

- Multi-Metal Compatibility: Works perfectly on MS, Aluminum, and alloys

- Controlled Process: Strict temperature, timing, and chemical quality monitoring

- Aesthetic & Functional Coatings: For both industrial and decorative applications

- Fast Turnaround: Efficient material handling and continuous process flow

Each batch undergoes thorough inspection for coating thickness, adhesion strength, and finish uniformity - ensuring top-quality results every time.

Applications and Industries

Our powder coating services cater to industries such as:

automotive, engineering, fabrication, electrical enclosures, architectural metalwork, industrial machinery, and consumer goods.

We handle everything from small precision components to large fabricated structures, maintaining consistent finish and protection.

Reliable Coating. Long-Lasting Protection.

At Anand Engineering Works, we deliver more than just a finish - we deliver protection, performance, and precision.

Our 7-tank pre-treatment and powder coating process ensures that every component leaving our facility is durable, corrosion-resistant, and visually flawless.

📞 Contact us today to discuss your coating requirements or to schedule your next batch for surface finishing.

Get a Quote

Interested in this service? Contact us for a detailed quote and consultation.